Surge Protection Solutions For Oil And Gas: Safeguarding Critical Infrastructure

Prioritizing surge protection, mitigating costly downtime, and guaranteeing uninterrupted operations.

In the high-stakes world of oil and gas operations, protecting critical infrastructure against electrical surges is paramount. From drilling rigs to refineries, pipelines to processing plants, every component of the industry relies heavily on electrical systems to function efficiently and safely. However, the volatile nature of these environments, coupled with the presence of heavy machinery and equipment, makes them susceptible to electrical disturbances, including lightning strikes, power surges, and transient voltage spikes.

Understanding the Risks

Electrical disturbances pose significant risks to oil and gas facilities, potentially leading to equipment damage, operational downtime, safety hazards, and financial losses. In such a demanding industry where downtime can cost millions of dollars per day, investing in robust surge protection solutions is not just a wise decision but a necessity.

Common Causes of Electrical Disturbances:

- Lightning Strikes: The oil and gas sector often operates in remote areas where lightning strikes are prevalent. A direct or nearby strike can induce high-voltage surges into electrical systems, causing extensive damage.

- Switching Operations: Rapid switching of heavy loads, such as motors and transformers, can generate transient voltage spikes, stressing the electrical infrastructure.

- Grid Faults: Utility grid faults, including short circuits and voltage fluctuations, can propagate through interconnected systems, impacting critical equipment.

- Equipment Malfunctions: Faulty equipment, aging infrastructure, and poor maintenance practices can contribute to electrical disturbances within the facility.

Importance of Surge Protection

Effective surge protection is essential for mitigating the risks associated with electrical disturbances in the oil and gas industry. By installing robust surge protection solutions, companies can:

- Protect Equipment: Safeguard vital equipment, including control systems, pumps, compressors, and instrumentation, against voltage surges and transient events.

- Ensure Safety: Minimize the risk of electrical fires, explosions, and personnel injuries by maintaining a secure electrical environment.

- Prevent Downtime: Reduce unplanned downtime and production losses by ensuring continuous operation of critical systems.

- Preserve Assets: Extend the lifespan of expensive equipment and infrastructure, reducing repair and replacement costs over time.

- Maintain Compliance: Meet regulatory requirements and industry standards related to electrical safety and reliability.

Selecting the Right Surge Protection Solutions

When choosing surge protection solutions for oil and gas facilities, several factors must be considered to ensure optimal protection and performance:

1. Environmental Conditions:

- Harsh Environments: Select surge protection devices (SPDs) designed to withstand extreme temperatures, humidity, vibration, and corrosive atmospheres commonly found in oil and gas facilities.

- Outdoor Installations: Opt for weatherproof and UV-resistant SPDs for outdoor applications, such as wellheads, pipelines, and offshore platforms.

2. Voltage and Current Ratings:

- Matched Ratings: Ensure that the surge protection devices have appropriate voltage and current ratings to handle the specific requirements of the electrical system, including peak surge currents and operating voltages.

3. Type of Protection:

- Point-of-Entry Protection: Install SPDs at the main electrical service entrance to intercept surges before they propagate into the facility, providing comprehensive protection for all downstream equipment.

- Point-of-Use Protection: Implement additional SPDs at critical equipment and control points to provide localized protection against internal and external surges.

4. Compliance and Certification:

- UL Certification: Look for surge protection devices that comply with relevant industry standards, such as UL 1449, ensuring reliability and performance.

- ATEX Certification: For hazardous environments, choose SPDs certified for use in explosive atmospheres according to ATEX directives.

5. Remote Monitoring and Diagnostics:

- Advanced Features: Consider SPDs equipped with remote monitoring capabilities, allowing real-time monitoring of surge events, status alerts, and diagnostic information for proactive maintenance and troubleshooting.

Conclusion

In conclusion, surge protection is a critical aspect of ensuring the reliability, safety, and efficiency of electrical systems in the oil and gas industry. By investing in robust surge protection solutions tailored to the unique challenges of the sector, companies can mitigate the risks posed by electrical disturbances, safeguarding their assets, operations, and personnel. Whether it’s protecting drilling rigs in remote locations or securing refineries against lightning strikes, proactive surge protection measures are essential for maintaining continuity and resilience in oil and gas operations.

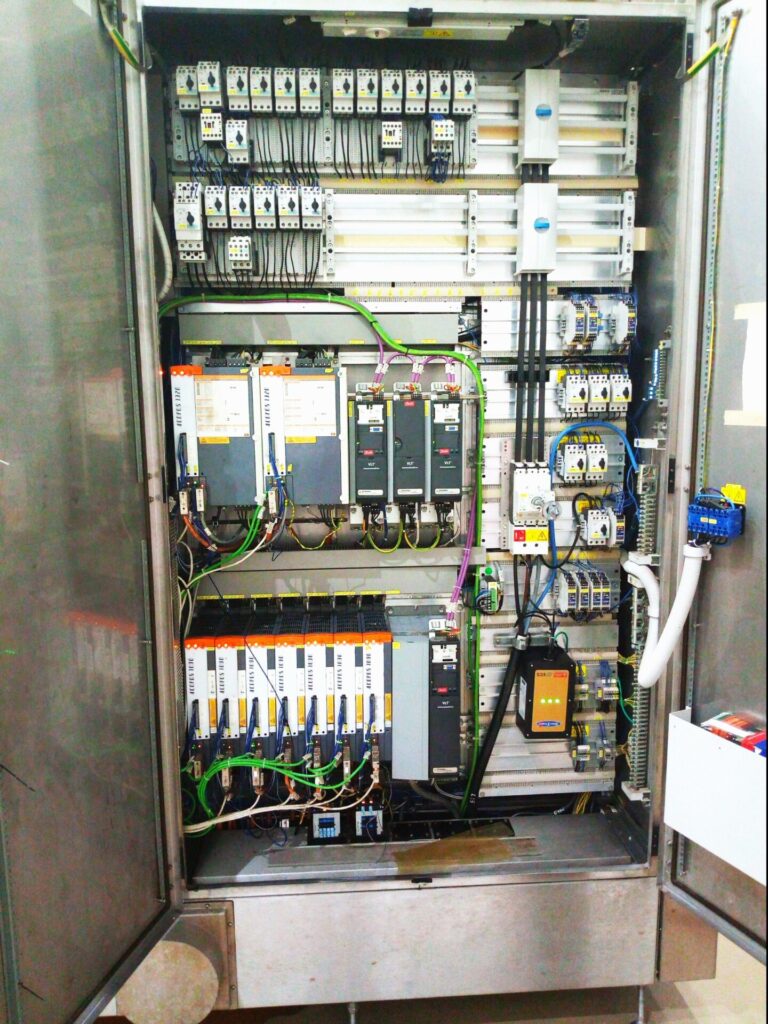

NBC Installations with Sinetamer Surge protector

Get Help In 3 Ways

Contact Our Experts: Reach out to our seasoned professionals who specialize in tailoring surge protection solutions for commercial properties.

Schedule a Consultation: Book a consultation to assess the unique needs of your business and receive personalized recommendations for advanced surge protection.

Invest in Security: Make the smart investment in the safety and stability of your business. Implement advanced surge protection strategies today.

sing up our newsletter

Sign up today for hints, tips and the latest product news - plus exclusive special offers.